Back in 2007, my Bob had trouble with his Allis-Chalmers D-15 tractor. He was using the tractor and loader, moving tree branches he had cut when suddenly the engine made a horrible sound. Somehow Bob was able to limp back up the lane to the machine shed before the poor old tractor went belly-up.

Bob knew right from the start that he had major problems. He didn’t have a lot of hope for it even when he started to take the engine apart. Deep inside the innards of the tractor, Bob found the starter had disintegrated, sending pieces of metal into the engine, wrecking it.

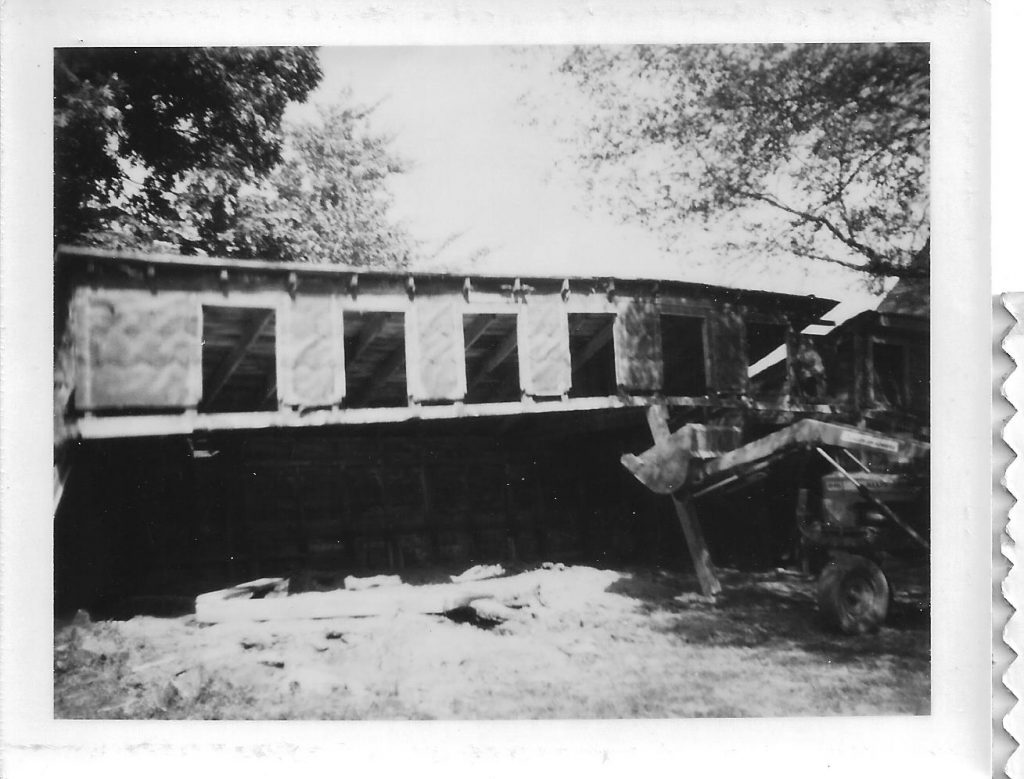

“What are we going to do now?” he said to the tractor. He had a couple of choices: try to rebuild that engine (parts would cost more than the tractor was worth), junk it and buy a replacement (if he could find one) or take the engine out of his other D-15 and make one out of two. He decided on the last choice and began dismantling the broken tractor, but first, he had to remove the loader.

The loader on the AC D-15 isn’t like new models that attach and detach with a quick click. There’s a lot more to it. While I was helping Bob take out pins and bolts, he started telling me about his first tractor with a loader.

“It was a John Deere A,” said Bob. “Up until then, we used pitchforks to clean out the barn and fill the manure spreader. This loader on the D-15 is modern compared to that A.

“First off the John Deere A had a narrow front end. It also had a hydraulic pump that worked off the Power-Take-Off (PTO). The only time you had power to the hydraulic pump was when the PTO was running. The thing with this tractor was the PTO stopped every time you disengaged the clutch.

“Let’s see if I can explain it to you,” he said to me. “You had to shift the tractor into neutral and engage the clutch to raise the loader. With that narrow front end every time you hit a hole you’d get stuck, especially when you had the loader full and since the loader only had a hydraulic lift you couldn’t use to get yourself unstuck.” (You should know that Bob is a pro at using the D-15 loader to push down into the ground to get out of trouble.)

“To dump the bucket, you’d pulled a lever that would trip it. There was no hydraulic on the bucket. If you were lucky, the spring would bring the bucket back into place. Otherwise, you’d have to lower it to the ground, back up, scraping it against the soil so it would latch back in place.

“Here’s how it went,” he said. “Every time you loaded the bucket, you would drive forward into the pile, disengage the clutch, shift into neutral, engage the clutch so the hydraulics would work, raise the loader up, disengage the clutch, shift into reverse, engage clutch to back up, disengage the clutch, put it in forward gear and engage the clutch to drive forward. You could raise the loader while you were moving, so if you planned ahead you would have it at the right height when you got to the manure spreader.

“If you screwed up, which I did a lot at the beginning, and needed the loader up some more to dump the bucket you had to stop, shift into neutral, engage the clutch, raise it up, disengage the clutch, shift into gear, move forward and then dump. But it still saved a lot of work. It was a heck of a lot better than using a pitchfork that’s for sure.

“This orange baby is an environmentally green machine now,” Bob said with a smile as he started it after making one running tractor out of two. “The only thing new on it is the oil filter. Even the tires are off an old combine.” (My husband is big into reusing what he has at hand.)

The D-15 was used when Bob and his father bought it in 1967. As Bob wiped the grease and oil from his hands he said, “I wonder if there are other farmers out there who keep an old tractor around just for old time sake? I kind of think there are.”

I too think there are farmers who have a love affair with their old tractors. If you’re one of them, drop Bob a line and tell him about the old machine you love or one you fondly remember. He’d like hearing from you.